Outstanding Durability and Adhesion

Not only does the hot glue labeler allow for more robust labels that can adhere to more challenging surfaces, but it also is able to finish the labeling process much quicker. Hot Melt Adhesive Labeling Technology: Hot glue labeling technology processes thermoplastic adhesives which are heated to form a strong, permanent bond. This is especially important if your product is exposed to water, hot or cold climates, or shipped with significant jostling. This is very unlike the cold glue or pressure-sensitive adhesives that are not so adhesive and eventually peel or wrinkle.

Cost Efficiency

By using a hot glue labeling machine, you will save a lot of labor cost right there on your production line. Hot melt products are generally less expensive than other labeling adhesives, per unit. The adhesive can also be used more accurately and wastage of the glue can be lowered as well. An average machine, for example, uses between 0.8 and 1.2 grams of glue per label, thereby providing a more cost-effective solution for customers without sacrificing quality.

Increased Production Speed

The fast and effective method of hot glue machines Suited for high-capacity production environments, the machines can handle between 150 and 600 labels per minute. Another advantage of the quick setting time of hot melt adhesive is the speed at which it can be processed since the adhesive does not need to dry, set or cure like cold glue or water-based adhesives. It improves the speed of the process, ensuring that there are no interruptions in the flow of production and that deadlines are met.

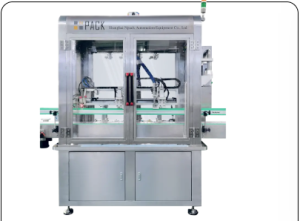

Works on multiple containers and labels

Versatility: Hot glue labeling machine can handle all sorts of container shapes, sizes, and materials; glass, plastic, metal, etc. They work with all sorts of label materials, from paper to foil and plastics. This versatility is crucial for multi-product companies that require one adaptable solution for many packaging requirements.

Greater Accuracy And Quality Control

Hot melt labeling devices ensure exact label placement at all times, which is fundamental to the great presentation of the products that have been packaged. The sensors and application heads are also advanced enough that each label is always placed the same way, guaranteeing perfect application that looks good on the product. This level of precision additionally minimizes errors and waste, ensuring that products appear consistent on shelves at the store.

Environmental Considerations

The labelling machine is also friendly to production as has natural cooling here i.e hot glue. Window Films On The Intelligent Side Adhesives employed are mostly solvent-free, and they give off no volatile organic compounds (VOCs). This is becoming increasingly important as businesses look to all manner of environmental regulations and simply reducing their carbon footprint.

Looking Forward

But if you are looking for a King of all labeling machine, opt for a hot melt glue labeling machine for your products, which is durable, cost-effective, and operate at very high speed, that makes it a perfect solution to enhance production capacities of your business. Many manufacturers have many raw materials and you can only imagine if they did hot melt adhesive labeling machine, it can do another business o85r practical, what is more, a hot melt adhesive labeling machine is a hot melt adhesive labeling machine contribute to the development of a manufacturer is a ONCE AND FOR ALL equipment.